Shell and Tube Heat Exchangers

Fluorotherm™ shell and tube heat exchangers are used for in-line heating and cooling applications for corrosive and ultrapure fluids. These units have been designed with efficient heat transfer as the primary purpose, offering a baffled cross flow heat exchanger. Our shell and tube heat exchangers are commonly used for oil refinery and chemical processes applications, and while they're similar to the immersion heat exchanger in terms of overall function, the shell and tube heat exchanger features an innovative design that facilitates the movement of fluids through both tubes and an exterior shell, providing heightened versatility.

Fluorotherm™ shell and tube heat exchangers are used for in-line heating and cooling applications for corrosive and ultrapure fluids. These units have been designed with efficient heat transfer as the primary purpose, offering a baffled cross flow heat exchanger. Our shell and tube heat exchangers are commonly used for oil refinery and chemical processes applications, and while they're similar to the immersion heat exchanger in terms of overall function, the shell and tube heat exchanger features an innovative design that facilitates the movement of fluids through both tubes and an exterior shell, providing heightened versatility.

Shell and Tube Heat Exchanger Design

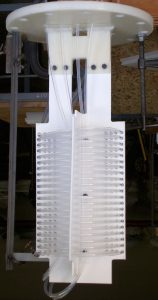

The tube side fluid flows through an ultrapure, chemically inert fluoropolymer pathway. The unit can be operated in cross flow, counterflow or parallel flow mode. The unidirectional shell and tube side flows allows for complete purging of the unit after a batch operation is completed. Also, since there is no flow reversal, the formation of stagnant pockets is eliminated during continuous or batch operation.

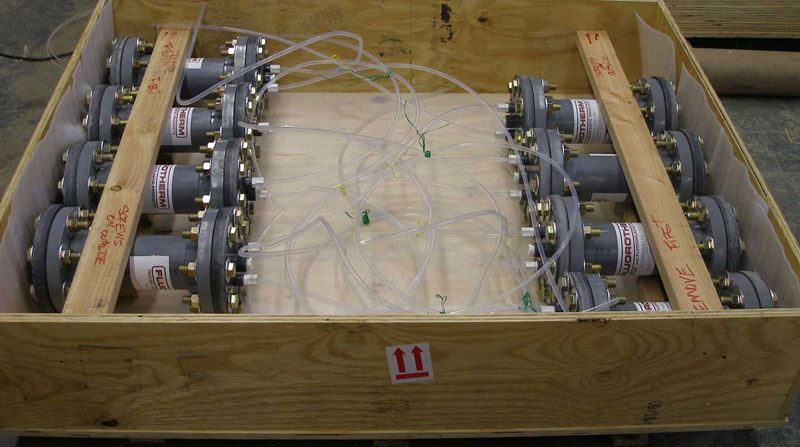

Fluorotherm™ offers shell & tube heat exchangers with heat transfer surface areas ranging from less than 1 sq. ft to 100 sq. ft. These sizes cover a wide range of applications for sanitary flow design (when needed). These include laboratory, scientific, sampling, and industrial cooling and heating applications. The unique feature of Fluorotherm™ designs is that they can be disassembled, inspected, cleaned and, if necessary, repaired.

Shell and Tube Heat Exchanger Materials

The current fluoropolymer materials of construction for Fluorotherm™ shell & tube heat exchangers are PVC, CPVC and PVDF for the shell, and PTFE tubing, FEP, PFA, or PVDF for the tubing. New materials, offering high chemical resistance and inertness for ultrapure fluids, are currently under investigation for our next generation of products for the semiconductor, green technology, laboratory, sampling, and general industry market segments.